Subscribe

29 September 2022

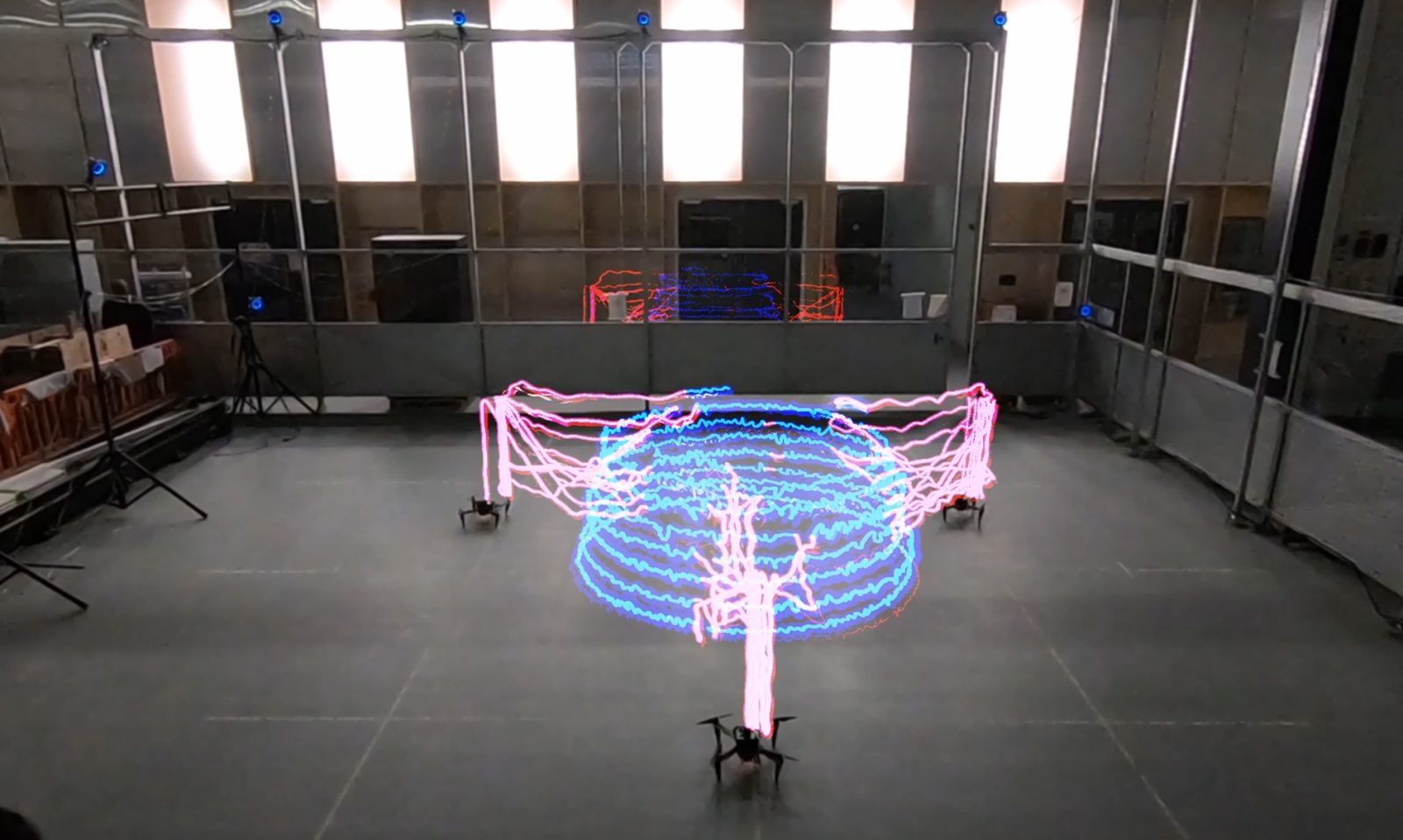

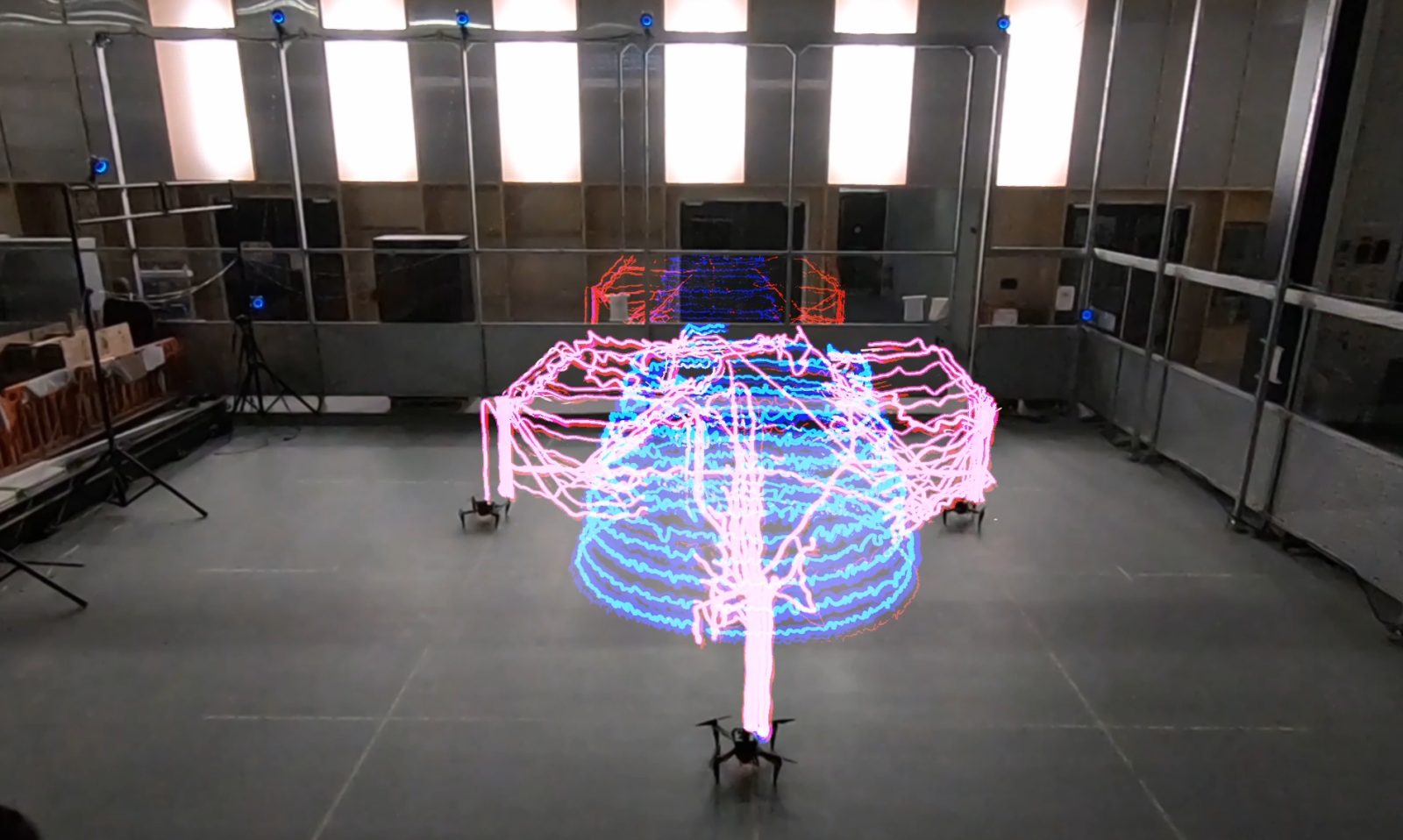

Source: Photos taken at the Imperial College London Aerial Robotics Laboratory by all partners (Imperial College London, University College London, University of Bath)

Source: Photos taken at the Imperial College London Aerial Robotics Laboratory by all partners (Imperial College London, University College London, University of Bath)

Source: Photos taken at the Imperial College London Aerial Robotics Laboratory by all partners (Imperial College London, University College London, University of Bath)

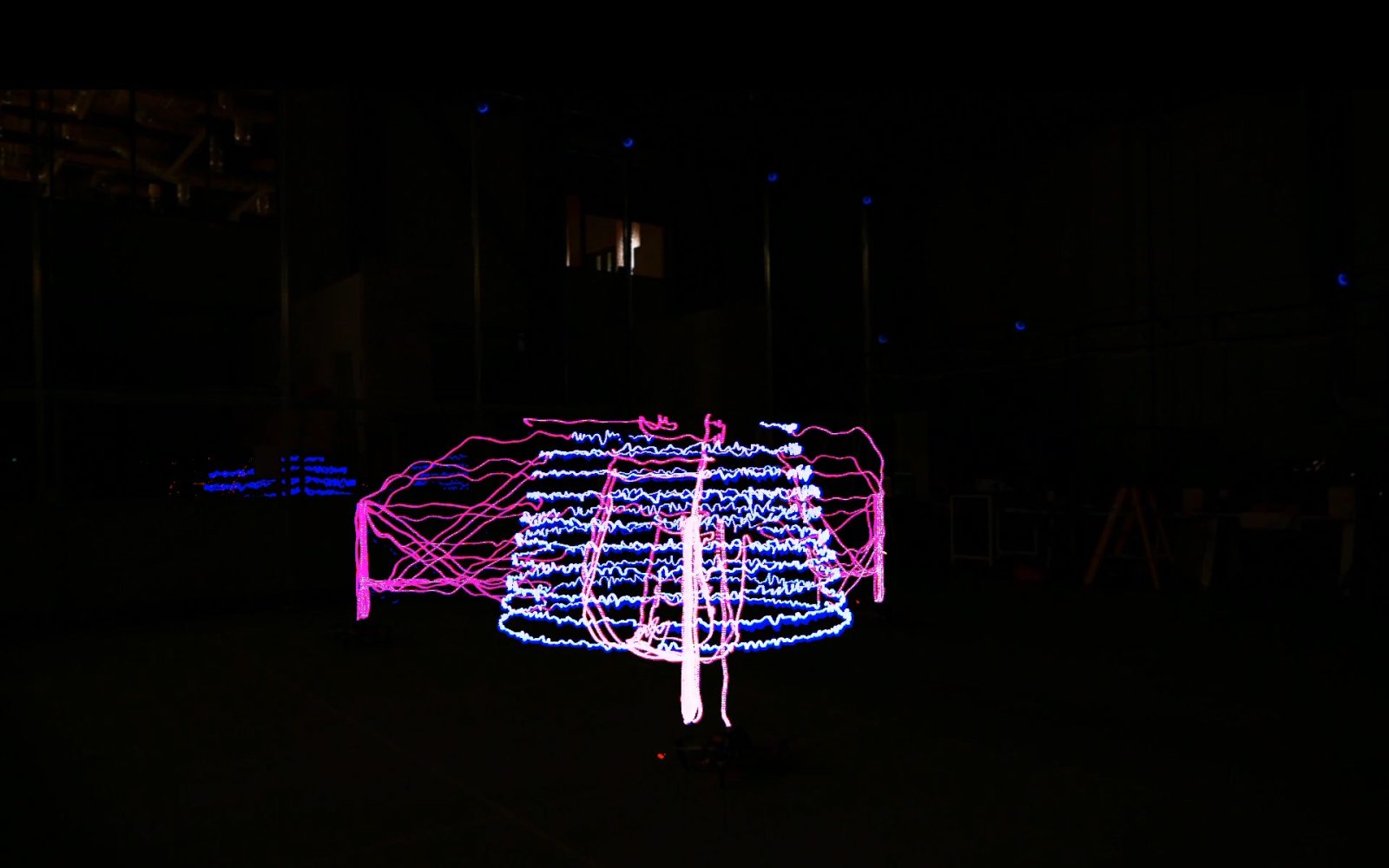

Source: Sarah Lever photography.

Source: Sarah Lever photography.

Source:

Source:

Source:

Source:

Source:

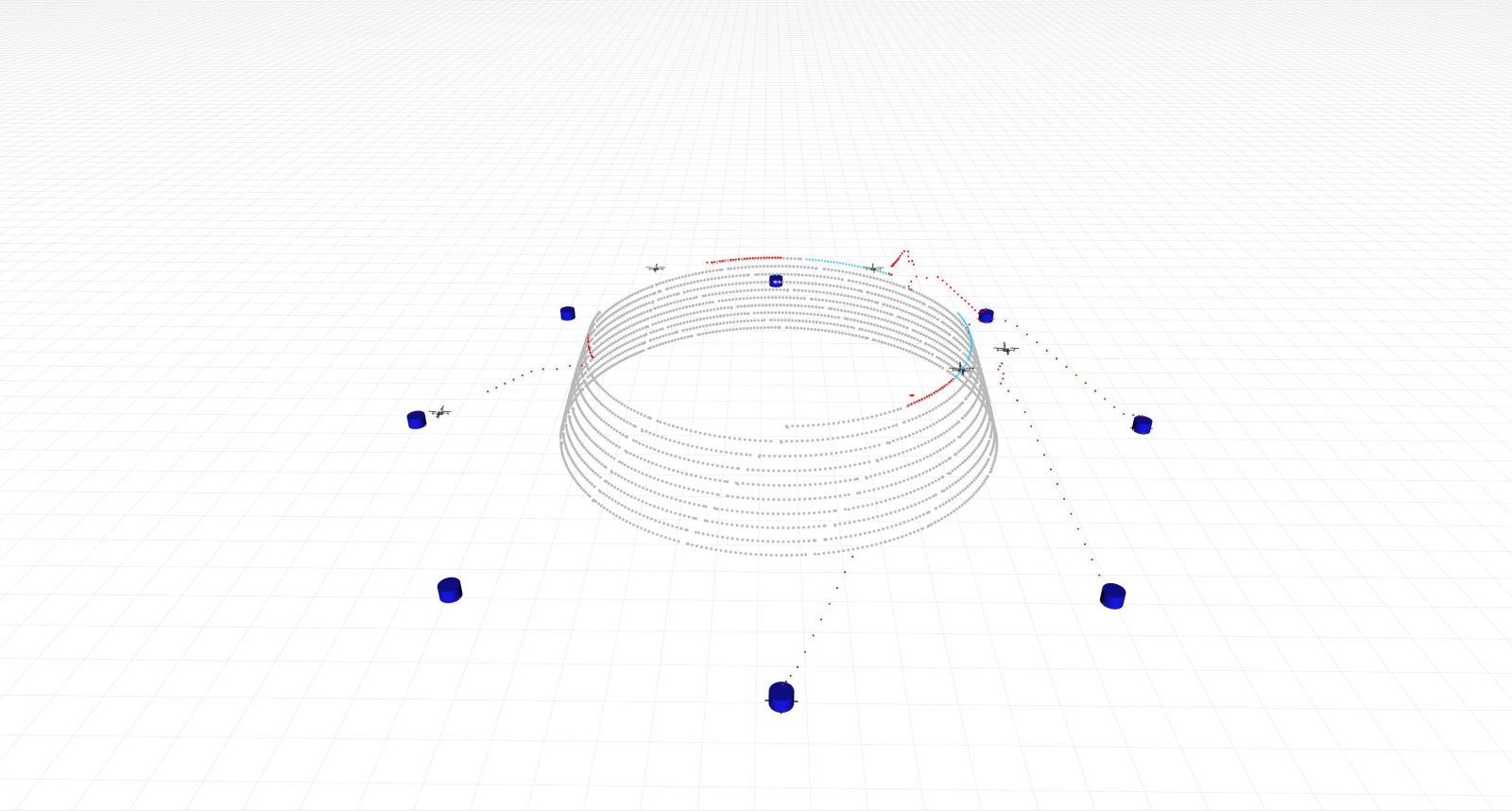

Source: Yusuf Furkan KAYA, Aerial Robotics Laboratory, Imperial College London and Materials and Technology Centre of Robotics, Swiss Federal Laboratories of Material Science and Technology

Source: Yusuf Furkan KAYA, Aerial Robotics Laboratory, Imperial College London and Materials and Technology Centre of Robotics, Swiss Federal Laboratories of Material Science and Technology

Source: Yusuf Furkan KAYA, Aerial Robotics Laboratory, Imperial College London and Materials and Technology Centre of Robotics, Swiss Federal Laboratories of Material Science and Technology

Source:

Source:

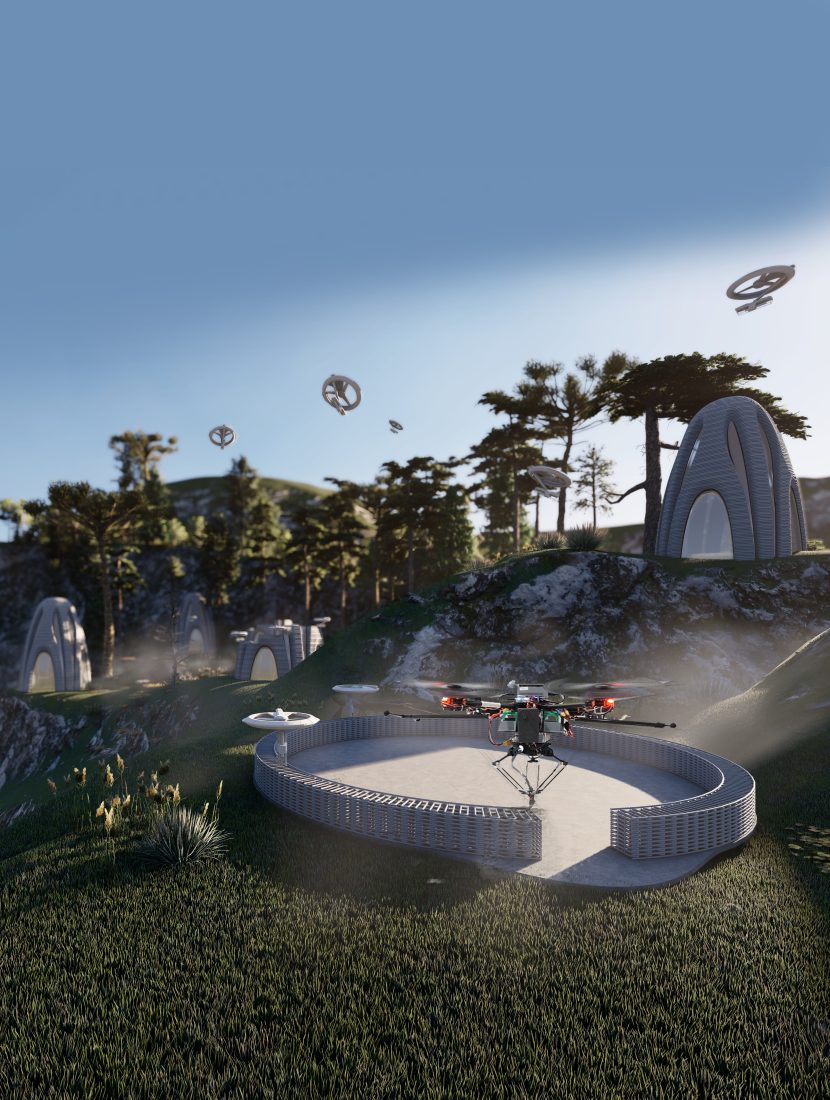

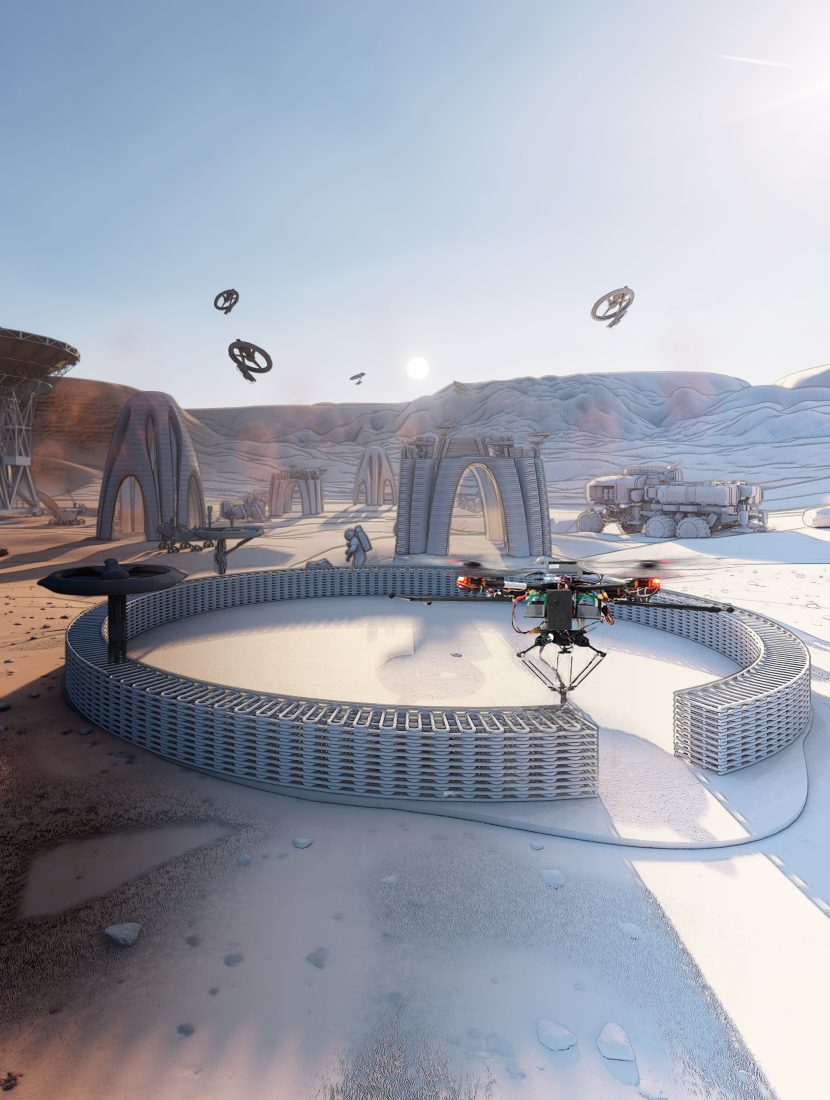

Researchers have developed a fleet of ‘bee-inspired flying 3D printers’ that can build and repair structures while in mid air

The team led by scientists at Imperial College London and Empa – the Swiss Federal Laboratories of Materials Science and Technology – claims the lab-tested system could be used for manufacturing and building in difficult-to-access or dangerous locations, such as high-rise buildings, or help with post-disaster relief construction.

The researchers have trialled the flying, 3D printing robots using ‘collective building methods inspired by natural builders like bees and wasps who work together to create large, intricate structures’.

According to the team, the drones in the Aerial Additive Manufacturing (Aerial-AM) fleet work co-operatively from a ‘single blueprint, adapting their techniques as they go’.

Although fully autonomous while flying, they are monitored by a human controller who checks progress and intervenes if necessary, based on the information provided by the drones.

Aerial-AM uses both a 3D printing and path-planning framework to help the drones adapt to variations in geometry of the structure as the build progresses. The fleet consists of BuilDrones, which deposit materials during flight, and quality-controlling ScanDrones that continually measure the BuilDrones’ output, informing their next manufacturing steps.

To test this concept, the researchers developed four different cementitious mixtures for the drones to build with.

Throughout the construction, the drones assessed the printed geometry in real time and adapted their behaviour to ensure they met the build specifications. The researchers said the drones achieved a manufacturing accuracy of 5mm.

The team’s proof-of-concept prints included a 2.05m-high cylinder (72 layers) with a polyurethane-based foam material, and a 0.18m-high cylinder (28 layers) with a custom-designed structural cementitious material.

Lead author Mirko Kovac, of Imperial’s department of aeronautics and Empa’s materials and technology centre of robotics, said the team had proved the drones could work independently and in tandem to construct and repair buildings – ‘at least in the lab’.

He said: ‘Our solution is scalable and could help us to construct and repair building in difficult-to-reach areas in the future.

‘We believe our fleet of drones could help reduce the costs and risks of construction in the future, compared to traditional manual methods.’

The UCL and Empa team was helped by a number of ‘co-investigators’ including Robert Stuart-Smith, Stefan Leutenegger, Vijay Pawar, Richard Ball, Chris Williams and Paul Shepherd, and their research teams at UCL, University of Bath, University of Pennsylvania, Queen Mary University of London, and Technical University of Munich (TUM).

The work was funded by the Engineering and Physical Sciences Research Council (part of UKRI), the Royal Society, the European Commission’s Horizon 2020 Programme, Royal Thai Government Scholarship and a University of Bath Research Scholarship.

The project was also supported engineer Buro Happold, the BRE, Skanska and 3D printing company Ultimaker.

The drone building concept comes as 3D printing continues to gain momentum in the construction industry.

Earlier this year Zaha Hadid Architects won the AJ100 Innovation of the Year prize for Striatus, a 3D-printed concrete bridge developed with Block Research Group at ETH Zürich.

The arched masonry footbridge was built with 53 3D-printed hollow concrete blocks, assembled without mortar or reinforcement.

comment and share

Tags3D printing drones Imperial College Innovation

“…polyurethane-based foam material, and…cementitious material”…?

Just because we *can* do something doesn’t always mean we *should*. So far most of the 3D printing going on isn’t in any way compatible with our net zero aspirations. When will we stop lauding high-carbon, high-toxin techno-gimmickry and start focusing on what’s actually needed?

or a new account to join the discussion.

We use cookies to personalize and improve your experience on our site. Visit our Privacy Policy and Cookie Policy to learn more. You can opt out of some cookies by adjusting your browser settings. More information on how to do this can be found in the cookie policy. By using our site, you agree to our use of cookies.