We use cookies to enhance your experience. By continuing to browse this site you agree to our use of cookies. More info.

An international team of scientists from Saudi Arabia, China, Pakistan, India, and Australia have collaborated on a new paper in Cement and Concrete Composites using machine learning to test foamed concrete.

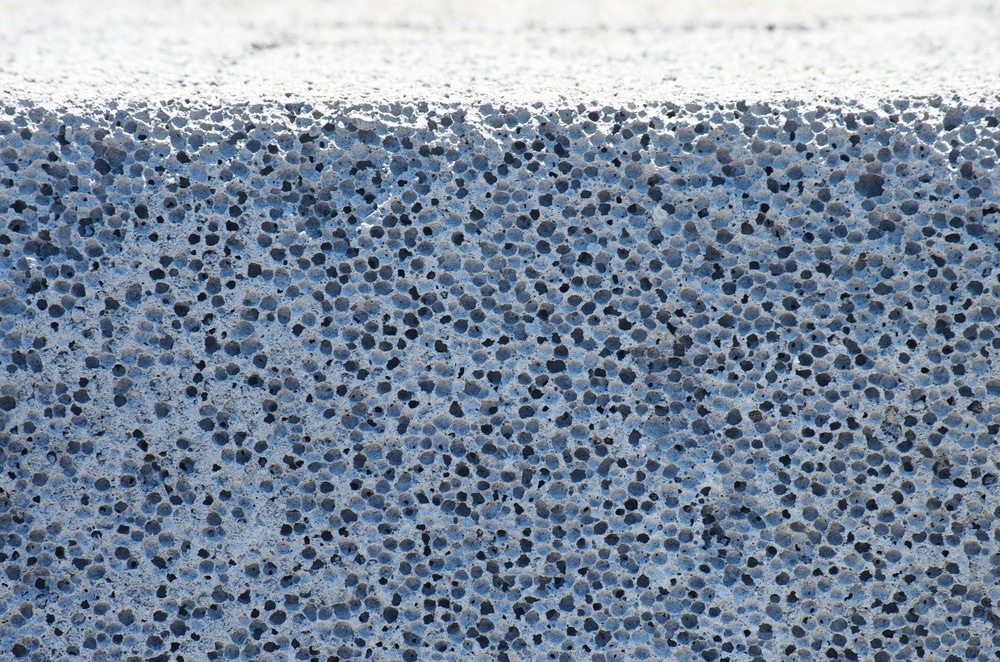

Study: Estimating compressive strength of lightweight foamed concrete using neural, genetic and ensemble machine learning approach. Image Credit: olpo/Shutterstock.com

Concrete has excellent mechanical and physical properties, especially when reinforced with steel rebars, which makes it an ideal construction material. However, concrete production comes with a huge environmental cost due to its carbon footprint and is a key source of climate change-inducing emissions. Moreover, concrete waste is a major source of environmental pollution.

Several sustainable types of concrete and cementitious additives have been researched in recent decades to partially or fully replace traditional ordinary Portland cement and improve the eco-friendliness of the construction industry, as well as enhance the mechanical, physical, and physiochemical properties of concrete. Foamed concrete is currently being explored by researchers.

This innovative material has a light cellular structure with varying density. Weight reduction in the binding mortar is caused by the inclusion of random air voids. Whilst not a new material, foamed concrete has become the focus of research due to its environmental and cost benefits compared to conventional concrete.

Other names for foamed concrete include low-density foamed concrete and lightweight cellular concrete. This material has been applied in fire-resistant and earthquake-resistant structures due to its excellent properties and is composed of cement, aggregate, foaming agents, and water. Several researchers have also investigated the inclusion of waste binders to improve the material.

The properties of foamed concrete can be influenced by material characteristics, such as cement mineralogy, type of foaming agent, and the granulometry of aggregates, as well as mixture proportions, the uniformity and nature of pores, and water quality. Additionally, curing methods can affect the final material properties and performance.

Determining the optimal mixture of foamed concrete material components is crucial for improving final product performance. Achieving the appropriate material blend imparts foamed concrete with an optimal high strength-to-weight ratio, which is vital for structural applications. Additionally, determining the optimal ratio of materials enhances fire resistance, energy consumption, and thermal conductivity.

The benefits of this material have led to its adoption in several countries such as Korea, the UK, and Canada. Currently, determining the optimal mixture of materials within foamed concrete is commonly performed using empirical models and experimentation, which can be inefficient.

Empirical models based on foundational models such as Feret’s and Balshin’s have been developed over the years, but there are challenges with these methods. For instance, the relationship between material properties and compressive strength is complex, and various constants must be used which are not easily determinable.

Due to the shortcomings of current empirical models in terms of complexity, time, and cost, researchers have turned to advanced AI-based models based on machine learning. These techniques provide several unique benefits over conventional methods due to the inbuilt abilities to overcome the complexities of critical problems and provide superior predictive power.

Intense research focus has been placed on applying machine learning to predict the compressive qualities of concretes prior to manufacture, which saves time, cost, and waste. Additionally, structural behavior can be predicted using machine learning algorithms. Machine learning-based techniques are fast becoming an integral part of research in the construction industry.

The research in Cement and Concrete Composites has employed three powerful machine learning algorithms (GEP, GBT, and ANN) due to their nonlinear capabilities. Specifically, the algorithms are used to predict the compressive strength of foamed concrete.

Material ratios of both water to cement and sand to cement were optimized using parametric analysis by the authors. Model performance, parametric analysis, and sensitivity analysis of variables are presented in the paper, and it has been proposed that a machine learning-based approach can be used to select the optimal foamed concrete composition.

The study revealed a strong correlation between foamed concrete density and compressive strength. Optimal algorithm parameters for the three machine learning-based models were also revealed in the author’s work. All optimized AI models yielded a strong R correlation, which reflects a strong agreement between the predicted and experimental results.

The GBT model achieved the best performance, with the highest validation data out of the three machine learning-based methods. In terms of accuracy, it surpassed the other two models, with ANN second and GEP being the least accurate.

Future opportunities exist in improving modeling and prediction further using machine learning algorithms, and the scientists involved with the paper have proposed that future research should investigate variable foaming agent dosages. Overall, the new paper has demonstrated the advantages of machine learning methods over conventional empirical and experimental models.

More from AZoM: How Does Laser Cleaning Technology Function?

Salami, B.A et al. (2022) Estimating compressive strength of lightweight foamed concrete using neural, genetic and ensemble machine learning approach Cement and Concrete Composites 104721 [online, pre-proof] sciencedirect.com. Available at: https://www.sciencedirect.com/science/article/abs/pii/S0958946522003146

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Written by

Reg Davey is a freelance copywriter and editor based in Nottingham in the United Kingdom. Writing for News Medical represents the coming together of various interests and fields he has been interested and involved in over the years, including Microbiology, Biomedical Sciences, and Environmental Science.

Please use one of the following formats to cite this article in your essay, paper or report:

APA

Davey, Reginald. (2022, August 23). Testing Foamed Concrete with Machine Learning. AZoM. Retrieved on August 24, 2022 from https://www.azom.com/news.aspx?newsID=59819.

MLA

Davey, Reginald. "Testing Foamed Concrete with Machine Learning". AZoM. 24 August 2022. <https://www.azom.com/news.aspx?newsID=59819>.

Chicago

Davey, Reginald. "Testing Foamed Concrete with Machine Learning". AZoM. https://www.azom.com/news.aspx?newsID=59819. (accessed August 24, 2022).

Harvard

Davey, Reginald. 2022. Testing Foamed Concrete with Machine Learning. AZoM, viewed 24 August 2022, https://www.azom.com/news.aspx?newsID=59819.

Do you have a review, update or anything you would like to add to this news story?

Cancel reply to comment

Andrew Terentjev

At the Advanced Materials Show 2022, AZoM caught up with the CEO of Cambridge Smart Plastics, Andrew Terentjev. In this interview, we discuss the company's novel technologies and how they could revolutionize how we think about plastics.

Ben Melrose

At the Advanced Materials Show in June 2022, AZoM spoke with Ben Melrose from International Syalons about the advanced materials market, Industry 4.0, and efforts to move toward net-zero.

James Vig Sherrill

At the Advanced Materials Show, AZoM spoke with Vig Sherrill from General Graphene about the future of graphene and how their novel production technique will lower costs to open up a whole new world of applications in the future.

This product profile describes the Flex Raman Catalog.

This is the full list of rotary evaporators offered by IKA Werke.

This product from Alicona features Cobots, which consist of a collaborative 6-axis robot and optical 3D measuring sensors to provide user-friendly measurement automation.

This article provides an end-of-life assessment of lithium-ion batteries, focusing on the recycling of an ever-growing amount of spent Li-Ion batteries in order to work toward a sustainable and circular approach to battery use and reuse.

Corrosion is the degradation of an alloy caused by its exposure to the environment. Corrosion deterioration of metallic alloys exposed to the atmosphere or other adverse conditions is prevented using a variety of techniques.

Due to the ever-increasing demand for energy, the demand for nuclear fuel has also increased, which has further created a significant increase in the requirement for post-irradiation examination (PIE) techniques.

AZoM.com – An AZoNetwork Site

Owned and operated by AZoNetwork, © 2000-2022